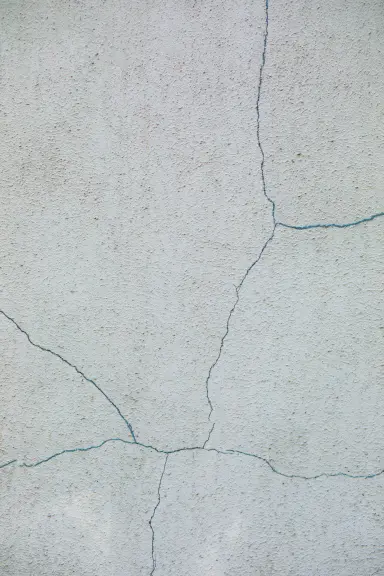

Thermal Cracking in Concrete Due to Temperature Fluctuations

Cracks in concrete due to thermal changes are a common occurrence, especially in regions with significant temperature fluctuations. These cracks result from the expansion and contraction of the concrete as it heats up and cools down. Here are the primary causes of cracks in concrete due to thermal changes:

- Temperature Fluctuations: Concrete expands when exposed to high temperatures and contracts when temperatures drop. Daily and seasonal temperature variations can subject the concrete to repeated cycles of expansion and contraction.

- Concrete's Coefficient of Thermal Expansion: Concrete has a coefficient of thermal expansion, meaning it expands or contracts at a specific rate for each degree Celsius or Fahrenheit change in temperature.This property varies depending on the concrete mix and aggregate used. 3.Restraint: Concrete is often restrained by its surroundings, such as adjacent structures, walls, or foundations. When one part of the concrete expands or contracts more than the adjacent portion due to temperature changes, it can create internal stresses, leading to cracking. 4.Size and Shape of Concrete Element: The size and shape of the a concretex element can influence the extent and location of thermal cracks. Large, thin slabs or long, narrow structures are more susceptible to thermal expansion and contraction.

- Inadequate or Missing Control Joints: Control joints are designed to accommodate the expansion and contraction of concrete due to temperature changes. If control joints are not properly installed, spaced, or maintained, uncontrolled thermal cracks may form instead.

- Time of Pouring: Pouring concrete during extreme temperature conditions can increase the risk of thermal cracks. Pouring concrete in very hot or very cold weather can lead to rapid temperature changes and differential expansion or contraction.

- High Cement Content: Concrete mixes with higher cement content generate more heat during the hydration process. This can accelerate temperature-related cracking, especially in mass concrete pours.

- Temperature Differential: Rapid temperature differentials between the surface and the core of the concrete can create thermal stresses. Sudden exposure to extreme temperatures, such as pouring cold water on hot concrete, can induce cracking. To prevent or minimize thermal cracks in concrete, consider the following measures:

- Control Joints: Install control joints at regular intervals to provide controlled locations for cracks to occur. These joints relieve stress and help prevent random thermal cracks.

- Proper Curing: Properly cure the concrete to minimize temperature differentials between the surface and the interior, allowing for gradual temperature changes.

- Timing of Placement: Avoid placing concrete during extreme temperature conditions, if possible. Early morning or late evening pours in hot weather, or the use of insulating blankets in cold weather, can help manage temperature differentials.

- Use of Low Heat of Hydration Cement: Consider using concrete mixes with cement types that generate less heat during hydration to reduce the risk of thermal cracking.

- Design and Expansion Joints: In larger structures, use expansion joints, which are wider and more accommodating than control joints, to allow for greater movement due to temperature changes