A Complete Guide To Pavement Quality Concrete: Definition, Purpose, Properties and More

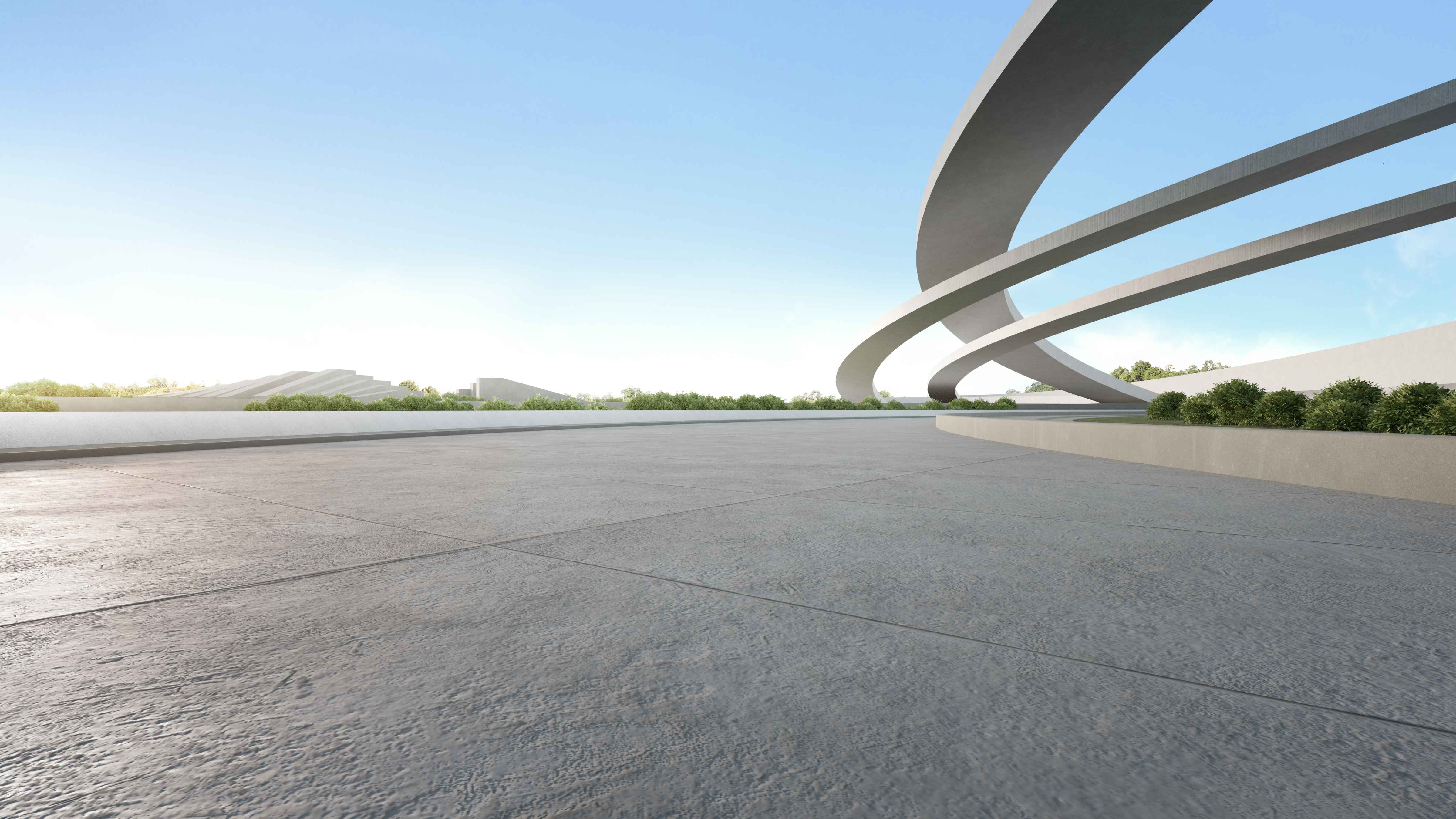

Building pavement, which stands for both sustainability and quality needs the right concrete solution. However, these days, you have plenty of options when it comes to concrete pavement solutions. This can make your task of selecting the right concrete solution more challenging than it has been before.

Nowadays, most leading construction businesses choose pavement quality concrete (PQC) for the highest quality pavement construction. Here, we will share a comprehensive guide to PQC for your help!

Definition of Pavement Quality Concrete

By definition, pavement quality concrete refers to a type of high-strength concrete made with large-size aggregates (mostly 31.5 mm). It is also popularly known for its short-from which is PQC. PQC has a grade of M40 and is mostly used for highway and pavement construction as the top layer. So, in simple terms, PQC is a high-strength concrete with large aggregates primarily used to construct the top layer of any highway or pavement construction. So, if you are looking for a high-strength concrete mix always choose pavement-quality concrete construction mix or PQC ready mix concrete solutions.

Purpose of Using PQC

PQC or pavement quality concrete is a high-strength concrete solution. It is mostly used for highways, pavements and airport runway construction. The primary purpose of using PQC or pavement quality concrete construction solutions is to give the pavement, highway or runway a solid and rigid surface. Usually, pavements, highways and airport runways tackle heavy-duty wheel stress 24/7. Therefore, commercial concrete mix construction such as PQC helps to distribute the stress evenly throughout the surface leaving a strong, durable and rigid surface.

Properties of PQC

PQC or pavement quality concrete consist of several chemical and physical properties. This might vary a little based on the PQC or Concrete Reinforcement Product provider you choose. However, the physical properties of PQC usually involve Sp. Gravity, water, lime reactivity, Blaine’s fineness and micron. On the other hand chemical properties of PQC usually include calcium oxide, silica, Alumina, Iron oxide, sulphur and manganese oxide.

How to mix the formulation and thickness of PQC

The mix of PQC formulation should be performed under a controlled environment and by only experts for the right thickness and quality. With the right ready mix PQC solutions you don’t need to stress over the mixing procedure or thickness. All you need to do is to get your suitable quantity and quality of PQC readymix concrete and follow the instructions given by the provider for mixing with water. The ideal PQC thickness is 250 and when you choose the right PQC solution you can easily mix PQC with the right Thickness.

PQC Area of application

If you are planning to use pavement quality concrete or PQC readymix for your construction, you should have a clear idea about where you can apply PQC or the right application area of PQC. Here are some common PQC areas of application we will list below-

- The upper surface of pavements

- The upper surface of the highways with a thick coating.

- Airport runway construction (on the upper surface of the runway) and other similar Areas.

Conclusion Using PQC Readymix is an easy and convenient way to construct heavy-duty and strong road construction. Above, we have discussed a comprehensive guide to pavement quality concrete including definition, purpose, properties, application area and more. For high-quality PQC and commercial concrete mix, only trust Firstchoice Readymix.